This article is based on an earlier Decent Espresso machine version. If you're interested in the history of our espresso machines, keep scrolling. If not, you can find info about our newest versions here and the machines themselves here.

We've been working for about a year, on replacement pieces that go inside the espresso machine group head, that direct water onto the puck.

A few goals we have:

getting copper out of the water path: there's always a worry about appearing in each batch of copper products we make. We have the tested by our own lab, each time, but still, it's a concern.

cleaner: coffee oils and particles seem to like to stick to copper, so regular cleaning to keep the best flavor, is important. Other materials are easier to keep clean.

better temperature accuracy: two things here.

First, copper is very much not an insulator, so it soaks up heat, and transmits that to water. That helps stabilize the water temperature, which is why traditional machines love all that metal, but it decreases our ability to quickly change the water temperature under software control. We want to do that (for instance) at the start of espresso making, to bring the coffee puck up to the defined brewing temperature

Secondly, the copper interferences with our ability to accurately measure the water temperature directly above the puck. We're instead measuring some water that hits the puck, and some water that's hitting the copper. If we make these parts out of an insulating material, we can get much more accurate coffee peak temperature readings, and then compensate both faster and more accurately.

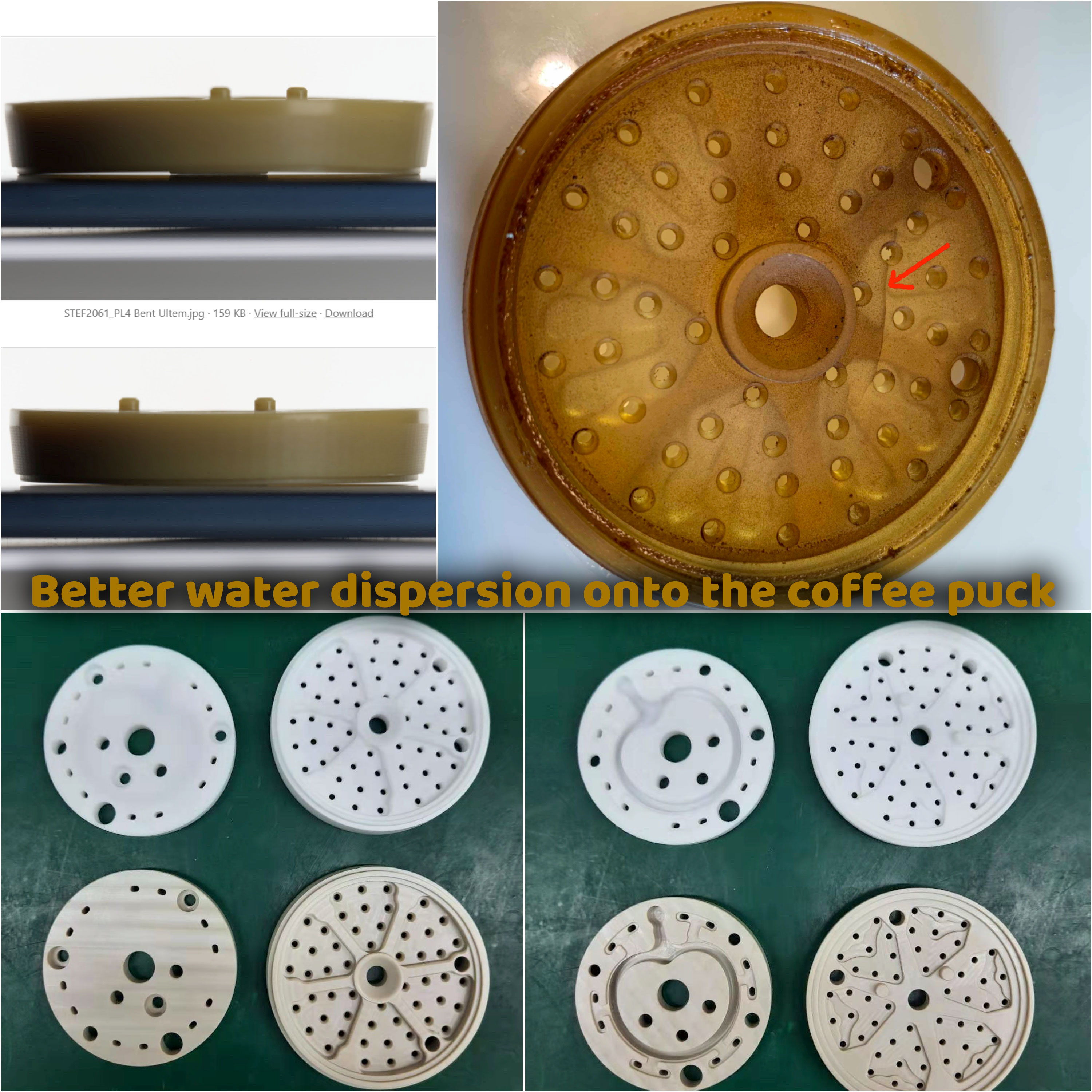

better water distribution: our water distribution approach is in two passes. First, we use the "apple shaped" path to break up the water's momentum and sendit through fairly large calibrated holes. Secondly, we have an array of precision machined holes directly behind the filter screen to evenly wet the puck. Our current design is already quite good at this, but we think we can improve it slightly.

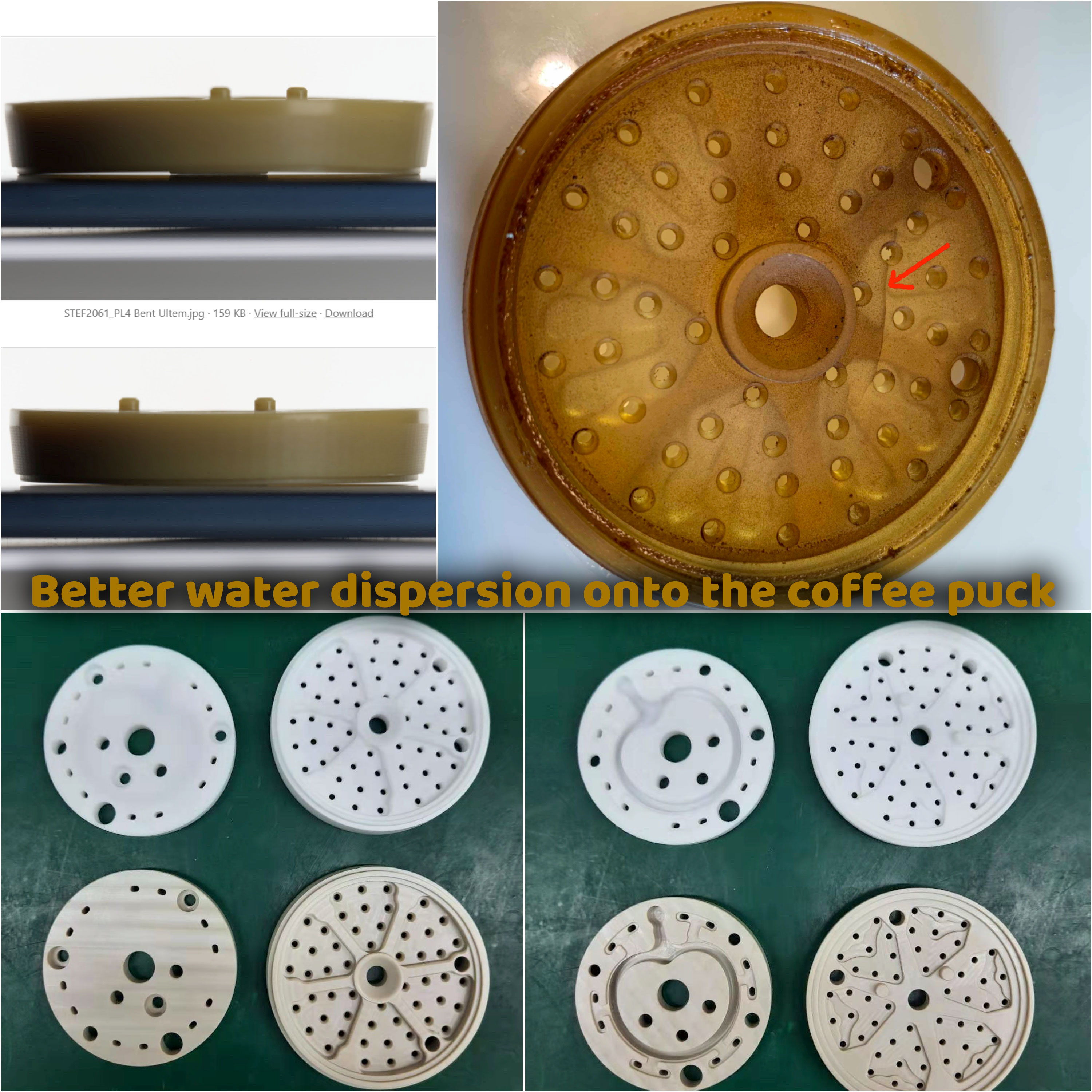

We've tested our designs made from a resin called Ultem. It's great stuff, used medically for in-body transplants, with no taste impact, and no safety concerns. However, we're finding that in about a third of our machines, cracks appeared after six month's use. Also, we're seeing a bit of warping over time, too.

So, we're now trying to different materials:

solid teflon: this is my preferred material. We already use solid teflon for our tubing, as it does not expand with heat (very useful) is very inert and well known to be food safe (except in very high temperature ovens, which isn't a factor here). It's also very anti-stick, so it should remain clean with minimal effort:

PEEK: this is really exotic and gorgeous stuff, even more expensive than Ultem. But, besides the very high cost (maybe overkill in this situation) it's another material I have to explain to people who ask. However, we know it'll work, if Teflon doesn't turn out to. We're considering PEEK for our mixing manifold, which has to withstand high pressure and lots of thermal cycling. https://www.curbellplastics.com/Research-Solutions/Materials/PEEK

Next year, we'll start to make this part, and it'll be offered as an optional low cost replacement for existing customers.

We're also increasing the thickness of this part by about 4mm, so bring the "head space" above a puck in line with the E61 standard. That will naturally increase the body/thickness of espresso, and there are several third-party "spacer kits" currently available that do this. For this that don't want the decreased headspace, you can move to a slightly larger espresso basket, to keep the same headspace as today.

More news on this, as we learn more.

-john

#R&D #upgrades #groupheadparts